Sewer Robotics has added artificial intelligence empowered automatic defect coding for videos that are recorded with the C70 video nozzle in the (free) Sewer Analytics web cloud.

Pipeline cleaning and surveying can be extremely tedious work, but there are options available to streamline the process. From recording High Definition video with a cleaning nozzle, to training AI-powered software to code defects automatically, Sewer Robotics has created effective solutions that make it easier and more efficient to clean and survey large amounts of pipes and to report their defects, even without human eyes reviewing the videos.

Take a look at how AI can be used to automate defect coding in cleaning videos and how it can help streamline the pipeline asset management process, from data collection and analysis to efficiently prioritize actions and define the measures to be taken.

C70 Video Nozzle

With the advancement of technology and engineering, new ways to clean pipes with advanced equipment have become available. One such equipment, the C70 video nozzle, is a jetting nozzle for pipe cleaning with an integrated forward lighting and battery powered, self-levelling, High Definition camera to record while cleaning pipes.

The C70 video nozzle is made of durable stainless steel and is compatible with any jetting truck by threading it onto the hose. The integrated pressure-switch activates the lighting and starts the recording when the pressure is on, so the cleaning operator focuses on operating the jetting truck and cleaning the pipe.

After the pipe has been cleaned, the video can be downloaded for an instant visualization of the pipe status to help the operator select the right cleaning approach. And in majority of cases, when cleaning proceeds without anomalies, the video is not reviewed in the field. But at the end of the day automatically uploaded to the Sewer Analytics online cloud along with the GPS coordinates, time and date of the cleanings.

AI Is Added For Cleaning Videos

Artificial intelligence, or AI, refers to machines that are capable of making smart decisions. These machines aren’t robots with arms and legs, but software programs that we use to make our lives easier by performing tasks that normally require human intelligence, such as understanding natural language, responding to images and sounds, and playing games.

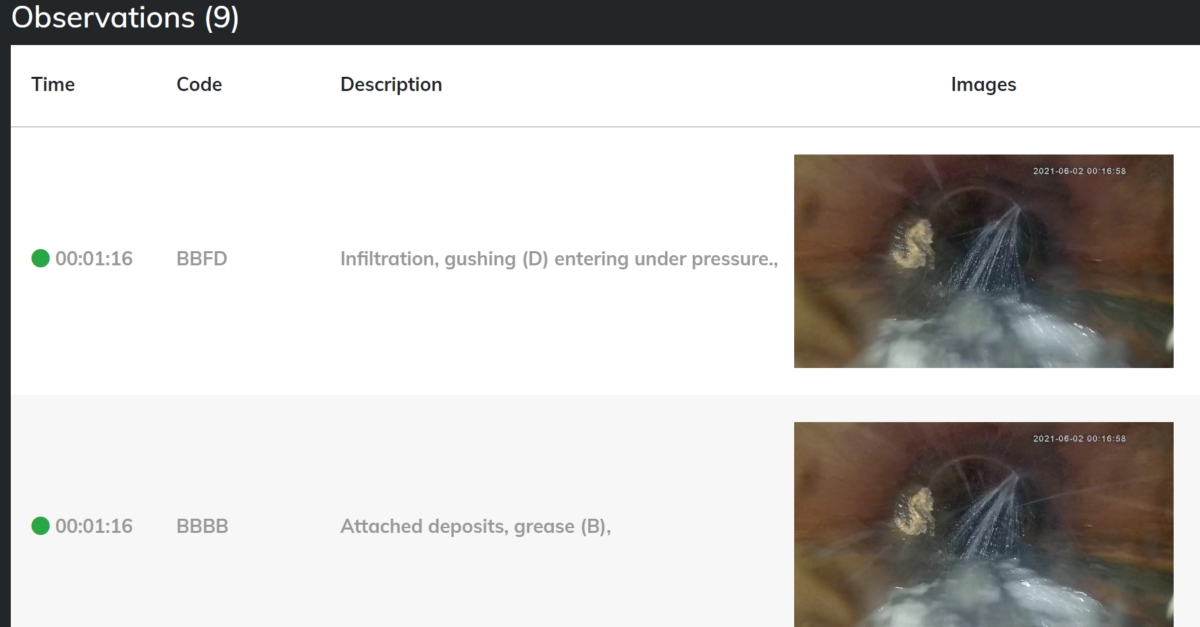

Artificial intelligence can also be used to automatically code defects in cleaning videos. This is done by first training the AI on pipe defects with a huge set of coded defects. Once trained, the AI then looks for patterns in the new video that matches the patterns it learned from the defective videos. Finally, the AI outputs a list of defects for the cleaning video, along with the required screenshot and defect code according international standards.

You do not have to necessarily look at the video as the AI will inform you that there is a grease deposit attached and a gushing infiltration inside the pipe, and classify the pipe segment as a number 5 high priority. Other common reported defects include roots, displaced joints, surface damage, fissures, cracks, settled deposits and intruding connections.

AI For Wastewater Infrastructure Management

As the world becomes more digital, organizations are turning to artificial intelligence (AI) for a variety of tasks. AI is even being used in wastewater infrastructure management. By using sensors and data analytics, AI can help identify issues with storm, water and sewer systems before they cause problems and is expected to revolutionize our industry to save organizations time and money by preventing damage to infrastructure and avoiding disruptions to service.

When it comes to cleaning and surveying pipes, you can use a video nozzle like the C70 and record a video in HD format during cleaning. and you can download it as soon as the cleaning process is completed. Indeed, it also allows the asset managers and cleaning crews to record high definition videos at a minimal cost during pipe cleaning operations.

Economic Benefits

Video nozzles are devices used for simultaneous pipe cleaning and video recording and can be used instead of conventional cleaning nozzles on any high-pressure cleaning truck during regular- or pre-inspection cleanings and do not require changes in methodology. The (video) data is therefore gathered at minimum additional costs and efforts compared to regular cleaning, which is always required before inspection.

As there is only a small part of the system, estimated between 15 – 30%, that does require additional measures and therefore the utilization of a video nozzle to collect video data will result in a significant cost reduction.

Although a video nozzle will not entirely replace a detailed CCTV crawler inspection, it comes at a much lower cost and it will tell you if there are any defects in the pipe. Depending on the reported defect and their priority, the right measures could be defined and implemented based on the cleaning video, or if preferred, a detailed CCTV crawler inspection could be carried out in the few cases where a detailed look is desired.

And, a HD video nozzle, like the Sewer Robotics C70, will provide video proof of the pipe segments that are perfectly clean and without issues to focus resources where they are required.

Visit C70 video nozzle for more information and videos.