FAST AND CONTROLLED BREAKDOWN OF SOLID OBSTRUCTIONS

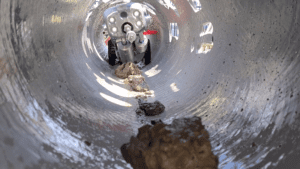

Precision water jet cutting applies a continuous adjustable high pressure/low volume water blast from a special designed crawler, with accurately steerable nozzle and CCTV camera module, for controlled removal of deposits settled and solid obstructions from within 150 – 1000mm (6- 40”) pipes and their lateral connections.

Eyes on the job and continuous adjustment of water pressure, angle with the pipe and distance to the material enable the operator to achieve the breakdown and elimination of various obstructions without adding damage to the pipe structure.

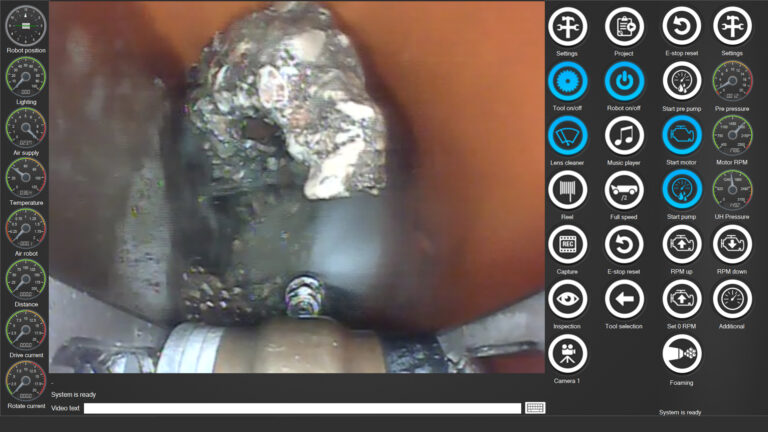

SEWER ROBOTICS high pressure units are built with digital controls and sensors for continuous pressure adjustments and immediate pump operation to adapt immediately to different materials and ever changing conditions without leaving the robot controls.

Our 15 years of UHP water jet cutting experience can be recognized in the designs and features of our precise and reliable directional cutting robots that are easy to operate and easy to service.

Made from durable stainless steel and with enough freedom of movement to apply a powerful water blast, directly to the material, under the right angle and with constant camera supervision in pipelines with varying diameters.”

Sewer Robotics offers 4 UHP water jet cutting modules, compatible with 3 different-sized crawlers for optimized application ranges, maximized in-pipe clearances and easy deployment from tight manholes.

These robots are all compatible with the same cable reels and control units and therefore easily exchanged. And if you only need a different size water jet occasionally, than we have loaner equipment available for you.

| WJ125 | WJ180 | WJ200 | WJ250 | |

|---|---|---|---|---|

| Pipe Diameter | 150 – 600mm (6-24”) | 200 – 500mm (8-20”) | 250 - 750mm (10-30”) | 300 – 1000mm (12 –40”) |

| Max. pressure | 3000bar (43,500psi) | 3000bar (43,500psi) | 3000bar (43,500psi) | 3000bar (43,500psi) |

| Ram lift | 210mm (8”) | N/A | 270mm (11”) | 520mm (20”) |

| Nozzle tilt | 110° | 90° | 100° | 90° |

| Compatible Robot | R125 | R160 | R160 | R250 |

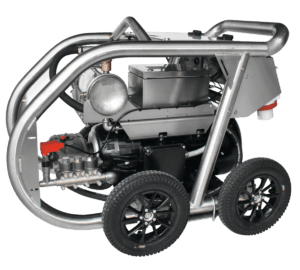

500, 1500, or up to 3000 bar?

Continuous pressure adjustment of Sewer Robotics high pressure units allow the operator to adapt immediately to different materials and ever

changing conditions from the control unit. High pressure units are available with a maximum pressure of:

▘500 bar (7,250psi)

▘1500 bar (21,750psi)

▘3000 bar (43,600psi)

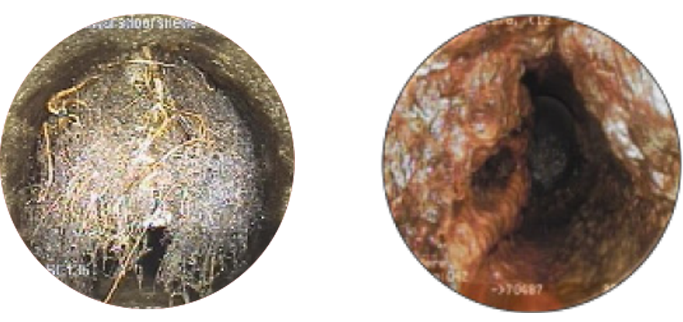

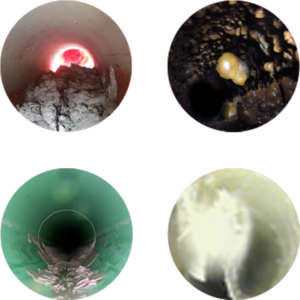

Precision water jet cutting removes: fog, debris, roots, cement, scale, tuberculation, grout, calcium & concrete.

| Material | Required max. water pressure | |

|---|---|---|

| + ROOTS + Grease | 500 bar (7,250psi) |

| + CEMENT + corrosion + scale + Grout + CIPP Liner | 500 – 1500 bar (7,250-21,750psi) |

| + Calcium + concrete + other Extremly hard materials | 1500 – 3000 bar (21,750-43,500psi) |

Compatible Configurations

Without delicate exterior parts and with a diameter of only 100mm (4”).

Its durable and short design provides ease of deployment from tight manholes and sufficient clearance to reach far inside pipes.

Of the electric movements (driving and rotating) allow operators to drive to the job fast. Then reduce the speed to maximize precision.

Convert the UHP water jet cutter into a powerful lateral reinstatement cutter- or CCTV inspection robot within 60 seconds. The available, purpose-build, modules widen the robot’s application range.

A wide-angle camera with continuously

adjustable LED lighting is placed directly

behind the cutter and easily cleaned with the

on-demand lens cleaner.

Water jet cutting uses a targeted high pressure water blast, precisely applied and continuously monitored, to remove roots, cement, grout, concrete, failed liners and mineral deposits without adding damage to the host pipe.

The position of the 90-degree, swivelling, nozzle connection ensures a wide application scope and maximized visibility during the operation.

The 205mm (8”) ram lift and 110° nozzle tilt provide a very wide application scope from 150 – 600mm (“6-24”) and are realized by hydro-pneumatic actuators.

These in-house developed, linear actuators are operated with compressed air and have an enclosed hydraulic circuit to combine the strength and precision of hydraulic cylinders with the convenience and serviceability of pneumatic actuators without hydraulics inside the robot.

Here you will find our most recent news articles

We are present at various international events and even host our own

Thank you for your online demonstration request.

Your preferred date and time will soon be reviewed and login to the online meeting shared. We are looking forward to meeting you.

Best regards,

Sewer Robotics

info@sewerrobotics.com

+3174 289475

+1 503 504 8474

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_EZKKSJCV16 | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_118483482_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |