Preparing pipes for CIPP lining

Removing the grease film and taking care of tree roots infiltrated from joints, cracks and lateral connections to prepare a

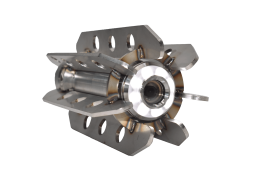

SEWER ROBOTICS was the first company to introduce UHP water jet cutting from a specialized crawler to remove solid obstructions and deposits settled. Our customers worldwide have removed many different materials and saved lots of pipes from replacement over the course of 15 years.

Removing the grease film and taking care of tree roots infiltrated from joints, cracks and lateral connections to prepare a

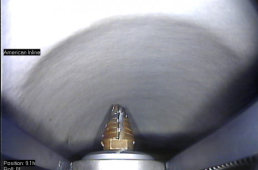

Have a look over the shoulder of this operator while he removes grout from this Sewer Pipe with the R125

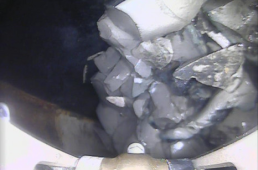

The concrete found its way into a 20” (500mm) drainage pipeline near the runways of a large Airport to settle

A grout mix meant for soil stabilization found its way into a vitrified clay sewer main pipeline during supportive construction

Root infiltrations from pipe joints and lateral connections are no problem for 500 bar (7,250psi) precision water jet cutting. Multiple

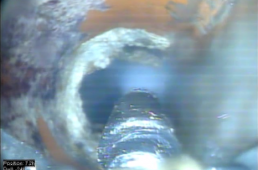

Limescale, the cristalized mineral deposits often found in sewer pipelines of hard water areas, has been succesfully removed from multiple

The Sewer Robotics’ robot R160 with the attached water-jet nozzle tool WJ180 was inserted into the pipe. A pump unit

Calcium mineral deposits had built up over years in this 250mm (10″) PVC pipeline and were removed with the Sewer

Here you will find our most recent news articles

We are present at various international events and even host our own

Thank you for your online demonstration request.

Your preferred date and time will soon be reviewed and login to the online meeting shared. We are looking forward to meeting you.

Best regards,

Sewer Robotics

info@sewerrobotics.com

+3174 289475

+1 503 504 8474

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_EZKKSJCV16 | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_118483482_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |