UVP125

(150-500mm | 6-20″)

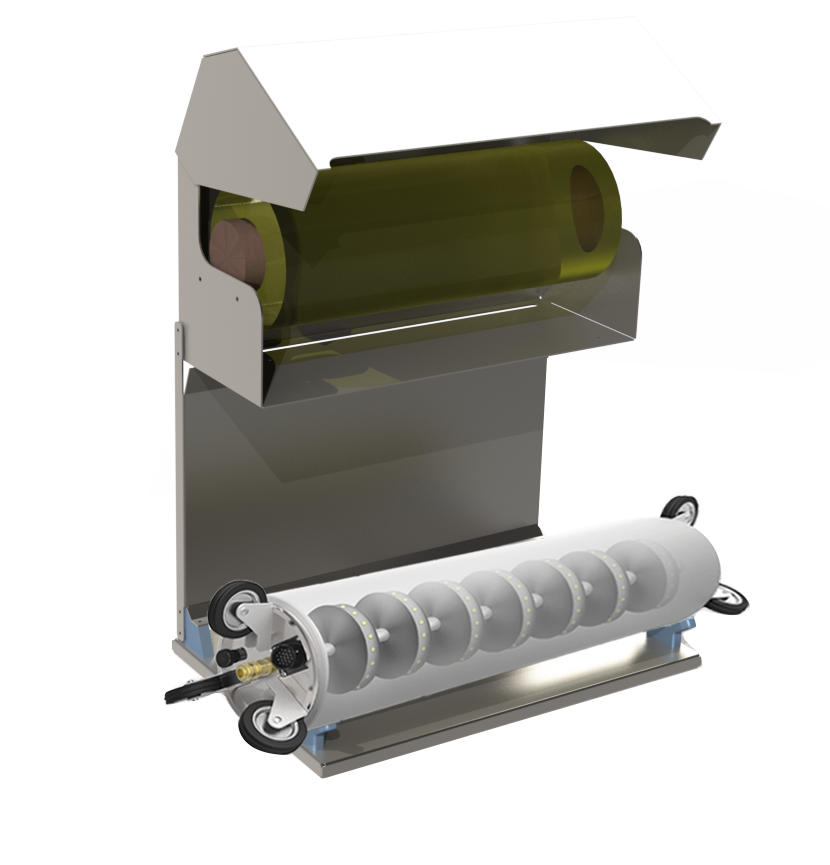

The UVP125 packer is made for rapid renovation from inside pipes made of concrete, steel, reinforced concrete, fibre cement, cast iron or PVC. longer damages can be rehabilitated by overlapping patches.

The Ultra Violet LED light-train has a low power consumption and is suitable for pipes of differing diameters from 150 to 500mm (6-20”) by easily exchanging the end-discs and bladders of the packer.

The UVP125 had a forward facing camera with LED ring and a variety of sensors inside to monitor the air pressure and curing temperature inside the bladder. And to measure the inflation and deformation inside the bladder.

The UV-packer can be used as an equipment module for the R125 crawler, or as stand-alone to be used with a cable, push robs or a suitable CCTV crawler.

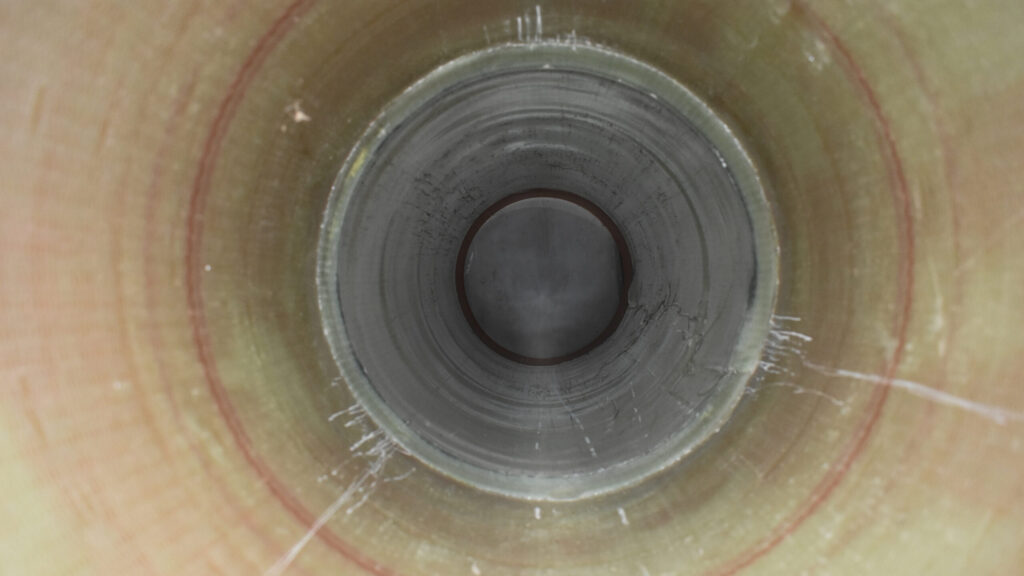

Pre-impregnated fibreglass liner on a roll

The UV-cured FIBALITE material is light curing glass reinforced polyester (G.R.P.), manufactured in a sheet form comprising a matrix of polyester resin, E-type glass reinforcement, special inert fillers and photoinitiator, sandwiched between two thin nylon protection films. The upper film, which is permeable for UV-light, stays during the application (with the exception of the overlap). Extra advantage is the very low emission of styrene and glass fibre particles during storage, transport and application.

The material is available in two thickness options: 1.5mm or 2.0mm. It can be installed either as a single layer with a thickness of 1.5mm or 2.0mm, or as a double layer stack with a maximum thickness of 3mm or 4mm.

Pan & tilt camera

The front-placed Pan & Tilt CCTV camera provides excellent vision to overview the installation process and to post inspect the freshly rehabilitated pipe immediately after the patching is completed.

Reinforcement : E-glass fibres (±70%)

Resin : UV curing ISO Polyester resin

Adhesion properties : >10 MPa (to steel, shot blast) (ASTM D4541)

Adhesive modulus : 3,8 GPa (ISO 527-2)

Thickness : 1,5/ 2,0/ 3,0 / 4,0mm

Adhesive tensile strength : ≥ 90MPa (ISO 527-2)

Flexural strenght : 20,486psi (ASTM D790)

Flexural modulus : 1,451,692psi (ASTM D790)

Roll length : 10m (33’)

Roll width (Patch lenght) : 600mm (24”)

Shipping dimensions : 750x260x270mm (29.5×10.2×10.6”)

Shipping weight : 20kg (44LBS)

UV liner on a roll

The UV- cured liner material is supplied on 600mm (24”) wide rolls. The roll is placed in the dispenser, which is designed to easily cut the liner at the right size, remove the protection film and load it on the packer by a single person in 3 minutes.

Scope of use

Curing time

Power

Max. pressure

Renovation lengths

: 150 – 400mm (6-16”)

: 6 – 10 Minutes

: 100-230V, 50-60Hz

: 2,5bar (360psi)

: 600mm (24”)

Scope of use

Curing time

Power

Max. pressure

Renovation lengths

Data logging

: 150 – 500mm (6-20”)

: 6 – 10 Minutes

: 100-230V, 50-60Hz

: 2,5bar (36psi)

: 600mm (24”)

: 900mm (36”)

: 1200mm (48”)

: Custom length

: Air pressure

: Deformation

: Curing temperature

Here you will find our most recent news articles

We are present at various international events and even host our own

Thank you for your online demonstration request.

Your preferred date and time will soon be reviewed and login to the online meeting shared. We are looking forward to meeting you.

Best regards,

Sewer Robotics

info@sewerrobotics.com

+3174 289475

+1 503 504 8474

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_EZKKSJCV16 | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_118483482_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |