System configurations

SEWER ROBOTICS rehabilitation robots can be used as a mobile configuration or installed in a van, trailer or box truck as stand-alone system with high pressure unit and water supply.

This economic mobile system configuration is compatible with all SEWER ROBOTICS crawlers and job-specific modules for electric cutting, CCTV inspection and UV spot repair.

This configuration is easily upgraded for UHP water jet cutting by adding a high pressure unit and second reel with high pressure hose.

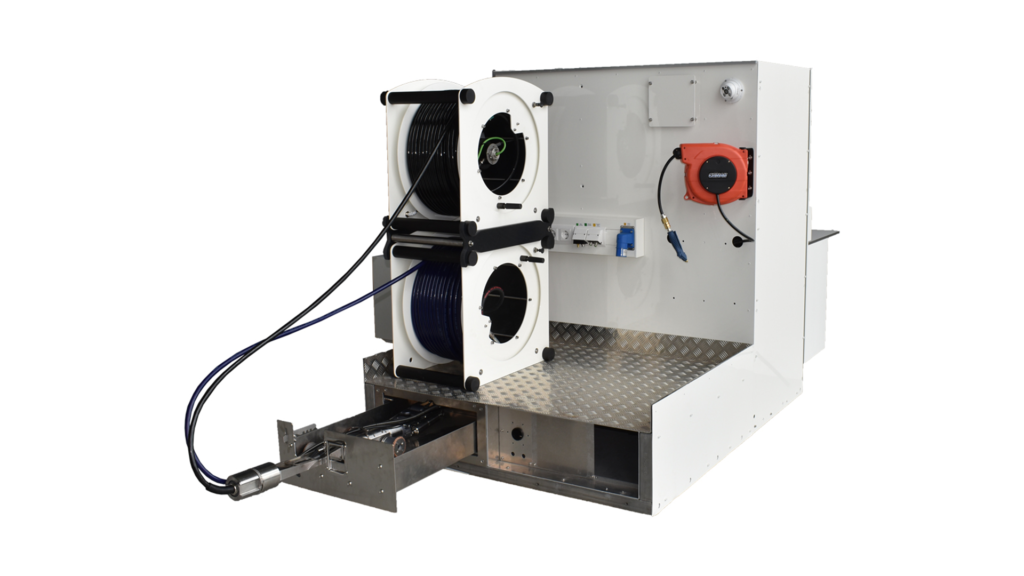

The cable- and hose reels have a small footprint for easement work and installation into any type of vehicle. This control system and reel can be used with PRO-JETTING’s tank cleaning- and industrial robots.

PC : 15.6” (1.920 x 1.080) Touch Screen Panel

Joysticks : Dual, 6-axis, responsive joysticks

Interfaces : Robot power supply, communication interface & video interface

Camera : Photo and video capturing with text overlay

Power : 100-230V, 50-60Hz

Dimensions : 540x410x225mm (21.3×16.1×8.9”) – closed

Weight : 18kg (39.7lbs)

Max. lengths : 120M (400ft) (Max. 100M(330ft for R600 and electric cutting))

Max. pressure : 1500bar (21,750psi)

Dimensions : 620x440x620mm (24.4×17.3×24.4”) Stackeable

Weight : 80kg (176.4lbs)

Compatible Robots : R125, R160, R250, R600, TWK300E

The ID-RIS operating software runs from a touch screen computer, displays live video and system data and allows remote control and continuous pressure adjustment of the pump.

All movements of the crawler, job specific modules and reels are operated from two programmable 6-axis joysticks.

The MH200R and MH200HD hybrid cable and high pressure hose reels are installed in heavy duty stainless steel frames with standard 150m (500’) and maximum 250m (820’) cable and high pressure hose. The reels feature cross-lead spindles, adjustable speeds, distance measurement and can be controlled individual or simultaneous from the reels, the control unit or a remote control.

HYBRID CABLE REEL

The Kevlar protected hybrid cable holds wiring for power, video and communication around an air supply hose for the pneumatic movements and positive pressure inside the transporter and modules.

HIGH PRESSURE HOSE REEL

The high-pressure hose supplies water under pressure for precision water jet cutting and reinstatement cutting operations. The MH200HD has an UHP swivel for pressures up to 1500bar (21,750psi).

*Individual Ultra high pressure hose segments and reels are available for pressures up to 3000bar (43,500psi).

Standard length : 150m (500′)

Max. lenght : 250m (820′)

Max. pressure : 1500bar (21,750psi)

Dimensions : 820x500x1020mm

(32.3×19.7×40.2”) each

Weight : 220kg (485lbs) each

Features

BATTERY POWERED CUTTING

SEWER ROBOTICS’ battery-powered cutting sets feature next-generation LiFePO4 battery packs with a smart Battery Management System (BMS) and inverter to support full-day cutting operations without running a generator.

Lithium Iron Phosphate (LiFePO4) batteries represent the latest generation of rechargeable lithium-ion (Li-Ion) batteries. Compared to the more traditional cobalt-based Li-Ion batteries, LiFePO4 batteries offer a longer cycle life, extended lifespan, better charge efficiency, and improved discharge. Additionally, LiFePO4 batteries are exceptionally safe and require no maintenance.

SOLAR ENERGY

For extended operation, solar panels can be installed on the roof of the unit to keep the batteries topped off during daylight hours. This enables continuous use even on lighter days, ensuring that the battery power remains optimally charged without the need for external charging sources.

This integration of solar energy enhances the system’s sustainability and minimizes charging times and costs.

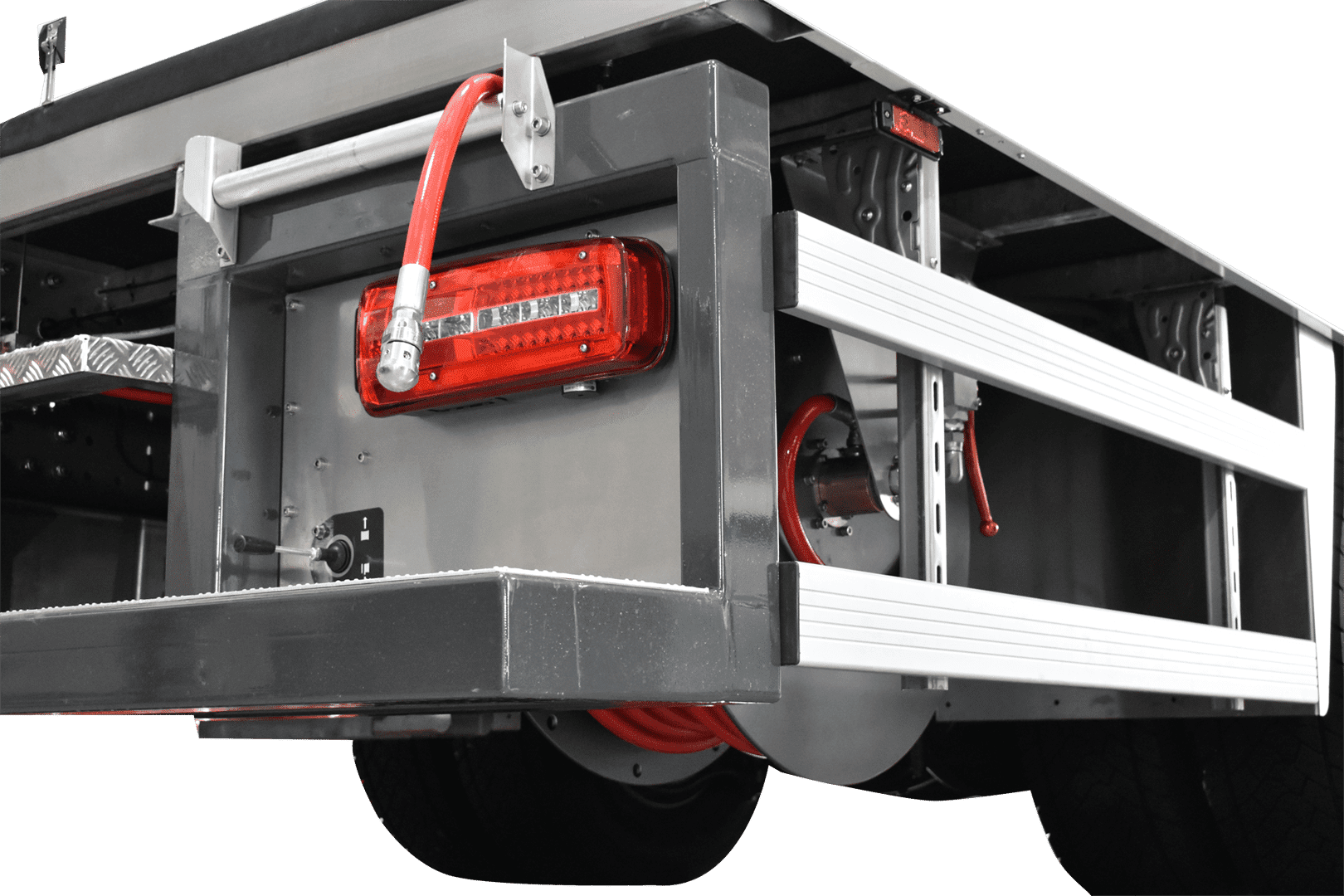

This plug-and-play skid offers a convenient and affordable solution for integrating SEWER ROBOTICS’ lateral reinstatement and precision jet cutting robot systems in vans, trailers and other vehicles.

With a 1000L (264gal) water tank, 3000W power inverter, operator desk with flush mounted joysticks and 27” touch screen PC, rear view camera, and robot storage drawer, it only needs to be anchored inside the vehicle and connected to the vehicle’s batteries.

Compatible reels : HH100 – 120m (400’)

: MH200 – 250m (820’)

Control unit : Flush mounted CP3D joystick panel & 27” Touchscreen PC

Compatible vehicles : Vans, trailers and trucks

Water supply : 1000L (264gal) or more

Power supply : 3000watt 100-230V, 50-60Hz inverter (12-24VDC)

Dimensions : 2400x1400x1620mm (94.5×55.1×63.8”)

Weight : 340kg (750lbs) (empty tank)

Vehicle GVWR : 3500kg (7,716lbs) with empty tank – or heavier

Compatible Robots : R125, R160, R250, R600, TWK300E

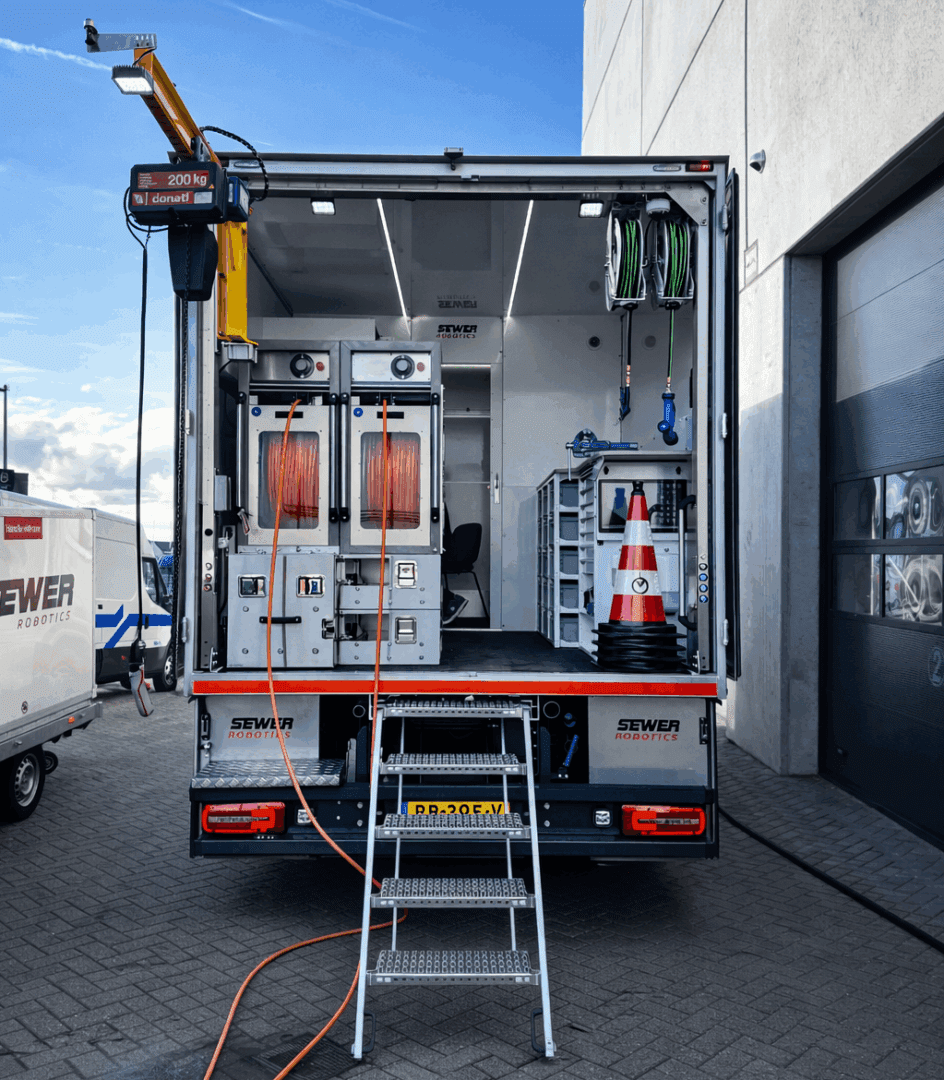

SEWER ROBOTICS box installations have everything exactly at the right place. Reels, robot storage and a workbench in the equipment compartment. Convenient touch screen controls and customizable joysticks, cabinetry with sufficient storage in a laboratory alike control studio and a powerful high-pressure unit with water- and power supplies in the engine room.

SEWER ROBOTICS box installations are built in our factory, with all bells and whistles, to meet

our quality standards and your (custom) requirements.

Such box integrated system is easily shipped inside a container and installed on a suitable

chassis anywhere in the world.

Jetting Capacity

By adding a jetting pump with hydraulic reel, the same precision cutting vehicle and crew can flush removed materials from the obstruction back to the manhole to increase daily production without requiring an additional jetting truck on site.

The jetting pump and hose reel can be driven by the same engine or PTO that drives the ultra high pressure pump

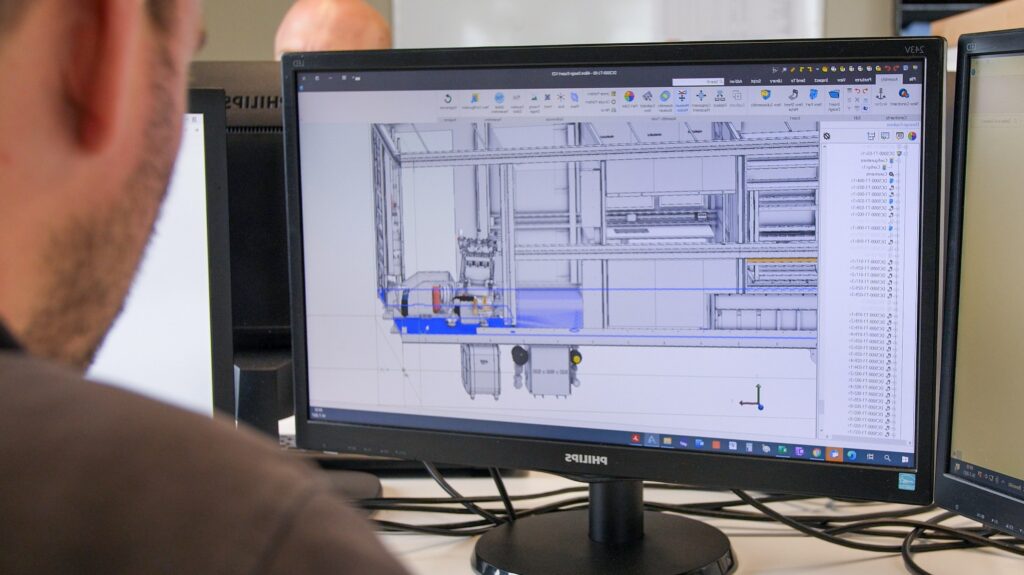

Custom is our specialty

We understand the importance to stand out from competition and invite you to share your ideas and custom requirements, so that our engineers can make your ideal equipment or vehicle integration reality.

Packer controls

A third joystick and pneumatic (top-hat) packer controls can be added to enhance operator convenience

permanent van intergration

With sufficient cabinetry, desk-integrated control unit and 27” Touch screen monitor in a laboratory alike operator studio.

single cable electric cutting

SEWER ROBOTICS electric cutter robots can be used in combination with a single hybrid cable to reach far inside the pipe.

Here you will find our most recent news articles

We are present at various international events and even host our own

Thank you for your online demonstration request.

Your preferred date and time will soon be reviewed and login to the online meeting shared. We are looking forward to meeting you.

Best regards,

Sewer Robotics

info@sewerrobotics.com

+3174 289475

+1 503 504 8474

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the "Advertisement" category . |

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| PHPSESSID | session | This cookie is native to PHP applications. The cookie is used to store and identify a users' unique session ID for the purpose of managing user session on the website. The cookie is a session cookies and is deleted when all the browser windows are closed. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _ga_EZKKSJCV16 | 2 years | This cookie is installed by Google Analytics. |

| _gat_gtag_UA_118483482_1 | 1 minute | Set by Google to distinguish users. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| CONSENT | 2 years | YouTube sets this cookie via embedded youtube-videos and registers anonymous statistical data. |

| Cookie | Duration | Description |

|---|---|---|

| test_cookie | 15 minutes | The test_cookie is set by doubleclick.net and is used to determine if the user's browser supports cookies. |

| VISITOR_INFO1_LIVE | 5 months 27 days | A cookie set by YouTube to measure bandwidth that determines whether the user gets the new or old player interface. |

| YSC | session | YSC cookie is set by Youtube and is used to track the views of embedded videos on Youtube pages. |

| yt-remote-connected-devices | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt-remote-device-id | never | YouTube sets this cookie to store the video preferences of the user using embedded YouTube video. |

| yt.innertube::nextId | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |

| yt.innertube::requests | never | This cookie, set by YouTube, registers a unique ID to store data on what videos from YouTube the user has seen. |